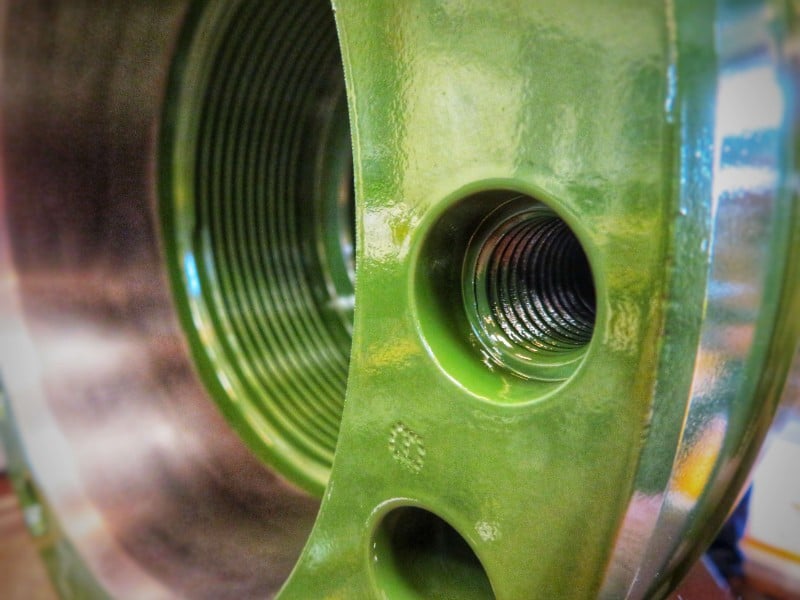

Ceramic Epoxy

Ceramic Epoxy coating is a unique abrasion resistant coating that protects by binding ceramic particles to a resin system, thus creating an encapsulating ceramic shell. Each ceramic particle is resin coated and becomes tightly packed in the cured film.

SERVICE INFO

| Ceramic Epoxy Coatings Statistics | |

|---|---|

| Adhesion (ASTM D4541, elcometer pull-off) | >3,680 PSI |

| Abrasion Resistance (ASTM D 4060, Tabor Test 1,000 cycles, CS 17 wheel, 1kg) | 27 milligrams loss |

| Surface Roughness (Profilometer value) | 20 Ra |

| Flexibility (ASTM D 522) | 15% elongation |

| Impact Resistance – Direct (ASTM D 2794) | 50 in-lbs |

| Thickness | .005″ – .010″ |

| Use Temperature | 300°F max |

| Static Coefficient of Friction (ASTM D 4518) | 0.152 mean static friction value |

| Dielectric Strength (ASTM D 149) | >1,750 volts/mil (>68 volts/micron) |

| Salt Spray (ISO 7253) | 6,000 hours |

| Cyclic Corrosion (ASTM D5894) | Pass |

| Fire Rating Over Steel (ASTM E84-91a) | Smoke Density – Class I Flame Spread – Class I |

| Chemical Testing (ASTM G 20-modified to 30 days at 75°F/23.9°C) HCI in H20: pH of 2.9 HF in H20: pH of 2.9 H2SO4 in H20: pH of 2.1 NaCI (10%) + H2SO4: pH of 2.9 NaCI (10%) in H20 |

No Change No Change No Change No Change No Change |

Range Of Coatings

We provide worldwide quality coatings to various sectors including but not exclusive to industrial, oil & gas, oil-refining, petrochemical, marine, construction, mining, engineering, electronics and the military.